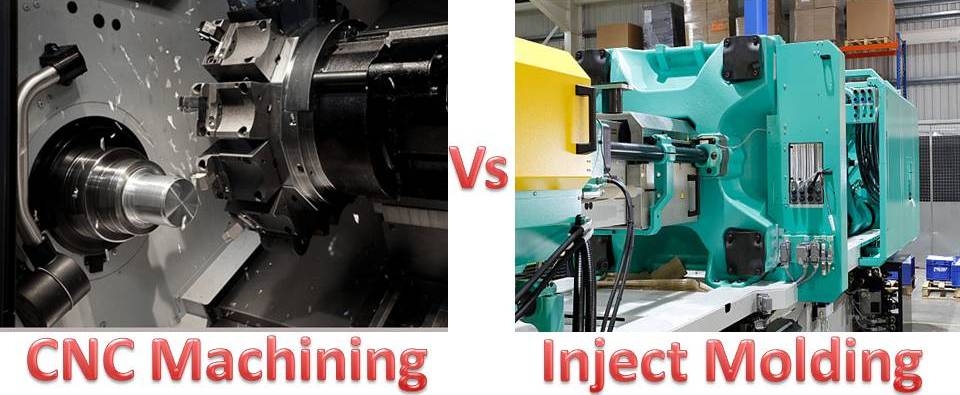

When it comes to manufacturing products, there are a few different methods that can be used. Two of the most popular are CNC machining and injection molding. But what is the difference between CNC machining and injection molding? And which one is right for your product? In this blog post, we will discuss the pros and cons of CNC machining VS injection molding, so you can make the best decision for your business!

What is CNC Machining?

CNC machining is a manufacturing process that uses computer-controlled machines to cut and shape materials. This process can be used to create products from a variety of different materials, including metals, plastics, and wood. CNC machining services is a versatile manufacturing method that can be used to create products of all shapes and sizes.

What is Injection Molding?

Injection molding is a manufacturing process that involves injecting molten material into a mold to create products. This process can be used to create products from a variety of different materials, including metals, plastics, and glass. Injection molding services is a versatile manufacturing method that can be used to create products of all shapes and sizes.

CNC Machining vs Injection Molding: Which is Right for Your Product?

Now that you know the basics of CNC machining and injection molding, you may be wondering which one is right for your product. The answer to this question depends on a variety of factors, including the type of product you are creating, the quantity of products you need, and the timeline for your project.

If you are creating a product that requires intricate details or a complex design, CNC machining may be the best option. CNC machining allows for a high level of precision and can create products with very tight tolerances.

If you need to create a large quantity of products, injection molding may be the best option. Injection molding is a faster manufacturing process than CNC machining and can be used to create large quantities of products quickly and efficiently.

Ultimately, the decision of which manufacturing process to use comes down to a variety of factors.

The advantages of injection molding

– Injection molding is a faster manufacturing process than CNC machining.

– Injection molding can be used to create products with complex shapes and designs.

– Injection molding is a more cost-effective manufacturing method than CNC machining for large production runs.

– Injection molded products have a high degree of accuracy and repeatability.

The disadvantages of injection molding

– Injection molding requires the use of expensive molds.

– Injection molding is not well suited for low volume production runs.

– Injection molded products can have surface defects.

The advantages of CNC machining

– CNC machining is a versatile manufacturing process that can be used to create products from a variety of different materials.

– CNC machining is well suited for low volume production runs.

– CNC machined products have a high degree of accuracy and repeatability.

The disadvantages of CNC machining

– CNC machining is a slower manufacturing process than injection molding.

– CNC machining is not well suited for creating products with complex shapes and designs.

– CNC machining can be a more expensive manufacturing method than injection molding for large production runs.