Introduction to robot control cabinets

Playing a significant role in the functionality and operation of industrial robots, control cabinets contain electronics, control systems, and other important components that are necessary for the execution of tasks. With the advancement of industrial automation, control cabinets become an integral part of robotic systems which also leads to an effective and seamless performance of these systems. They serve as the heart of industrial robots, thus, having an indispensable role in the industry.

Role of control cabinets in the industrial robot system

Control cabinets are an important part of industrial robotic systems as they serve as the center of their operation. Therefore, these control cabinets are of utmost importance which control and coordinate the movements of the industrial robots. Moreover, these cabinets also act as a communication hub that facilitates easy interaction between the robot and its various elements.

Importance of introducing power in control cabinets

For the smooth functioning of the industrial systems, it is crucial to introduce power into these cabinets. They not only enhance safety, and centralize control but also optimize space in the industrial and commercial settings. Minimizing the risk of human error while ensuring efficient operation is the most important role of the introduction of power into these control cabinets.

Role of power in control cabinets

In the regulation and optimization of electrical systems, control cabinets play a crucial role across diverse industrial applications. The primary concern is safety in which, control cabinets play a significant role as they eliminate many of the risks that are involved. Thus, safeguarding expensive machinery from unnecessary harm and also minimizing downtime for maintenance.

- Different power supply types and specifications

Definition of alternating current (AC) and direct current (DC) power supplies

These are two fundamental types of electrical currents that vary in the direction of the flow of charge. Alternating current is the predominant form of electricity that has a voltage that changes continuously from positive to negative. Direct current which is most commonly found in batteries, is known for its stability. However, it is far less efficient for long-distance transmission as compared to alternating current..

Characteristics of alternating current (AC) power supplies:

- Direction of current: AC power supplies mostly show fluctuations in the direction of current flow. This flow changes between positive and negative.

- Power transmission: It is well suited for long distance power transmission as the transformers can easily change the voltage level which lessens energy loss during transmission.

Characteristics of direct current (DC) power supplies

- Direction of current: direct current retains a continuous flow of electric charge which is in one single direction; from positive to negative.

- Power storage: DC is perfect for portable electronic devices that is why it is most commonly associated with batteries where energy is stored chemically and released when needed.

Power supply types with specifications commonly used by manufacturers are listed below

- ABB

Switching power supply: ABB utilizes switching power supplies due to their efficiency and compact design.

Uninterruptible power supply (UPS): ensures a continuous and reliable power supply thus, protecting important equipment from any danger.

Power inverters: ABB manufactures power inverters for converting DC to AC power which is necessary in renewable energy systems.

- KUKA

This manufacturer depends on various power supply types which are engineered to meet the growing needs of robotic systems.

Switching power supplies convert AC to stable DC. This boosts high reliability and compliance with industrial automation.

KUKA employs UPS to provide a constant and reliable power source with guards critical equipment from any disruptions.

- YASKAWA

YASKAWA depends on specialized power supply types to control the efficiency and precision of its automation solutions.

For optimal performance, this manufacturer has advanced technologies and reliable power sources. It also employs power inverters to convert DC to AC which is pivotal in applications where precise control is needed.

- FANUC

This employs specialized power supply types for the enhancement of the performance and reliability of its automation solutions.

Like the previous manufacturers, FANUC also uses UPS for constant power, power inverters to convert DC to AC, and provides a consistent power source which is crucial for its robotic systems.

- Stability and reliability of power supply

Importance of stable power supply to the robot control system

A stable robot power supply is the fundamental requirement for the safety, precision and reliability of the processes carried out in industrial settings. As robots rely on control signals, it is crucial to prevent any fluctuations in the power supply. Furthermore, fluctuations in voltage may lead to downtime and permanent damage to the equipment.

Power supply design and technology that ensure stability and reliability from the following manufacturers:

- ABB

Their holistic approach to power supply shows its commitment to always providing perfect solutions that meet the demands of the advancing industrial and commercial applications.

- KUKA

They prioritize stability and reliability in their power supply solutions with the main focus being on precision and accuracy of the robotic operations.

- YASKAWA

They place a strong emphasis on stability through design technologies which enhances the performance and longevity pf these automation solutions.

- FANUC

They meet the stringent demands of manufacturing and automation industries, where smooth performance is of utmost importance.

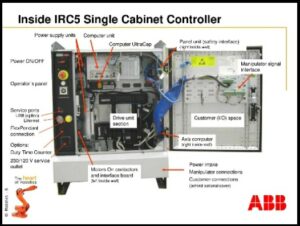

[Alt: ABB Cabinet Controller power supply unit/ The picture comes from: ABB website]

- Future trends and developments

Application prospects of renewable energy in robot control cabinet supply

- Reduced carbon footprints: transferring to renewable energy sources can significantly reduce carbon footprints.

- Hybrid systems: the combination of solar, wind, and traditional power sources creates hybrid systems that offer flexibility.

- Cost savings over time: the initial cost may be substantial but the long-term benefits make renewable energy solutions economically viable.

- Solar power integration: it allows harnessing solar energy to power control systems and can be highly useful in places where ample sunlight is available.

Development trends in intelligent power management systems

Increased integration of artificial intelligence and machine learning enable proactive energy optimization. Moreover, smart grids and demand-response technologies enhance grid reliability and its efficiency. Many energy storage solutions such as modern batteries balance the supply and demand.

Further efficient power supply design

Many power supply designs are emerging as prominent trends in the development of the management systems. Microgrid executions enable localized energy generation, distribution, and consumption, and resilience. Moreover, advancements in power electronics, such as wide-bandgap semiconductors, participate in reduced energy losses during conversion processes. Energy-efficient components and designs, paired with optimized cooling systems, guarantee minimal waste.